The Dutch-based Fibersort consortium has introduced the market-ready Fibersort device to market with a cutting-edge automated sorting system that transforms the recycling of textiles into postconsumer textiles. As an outcome of a lengthy duration of research, this technology will open new avenues for the reuse of textile wastes.

The Pile of Textiles Used In The Industry Keeps Growing

The increasing consumption and disposal processes in the fashion industry cause textiles that enter the market to come to final use quickly. Within North-West Europe alone, around 4,700 kilograms from postconsumer waste textile waste are produced each year, which is a tiny fraction of the worldwide mountains in textile waste. On average, just 30% of these wastes get recycled. Differently, the remainder is being thrown away in household waste. If all goes well, the textiles are offered for sale in the second-hand marketplace both locally and internationally. The remainder of textiles is deemed non-wearable because of their ineligibility to the second-hand market or the market over-saturation that second-hand clothing is currently experiencing. Most of these are being used for recycling, either disposed of or landfilled. However, 24% of textiles found can be reused into new textiles; however, they currently are not. They comprise 486-kilogram tones annually, which is equivalent to fifty Eiffel towers!

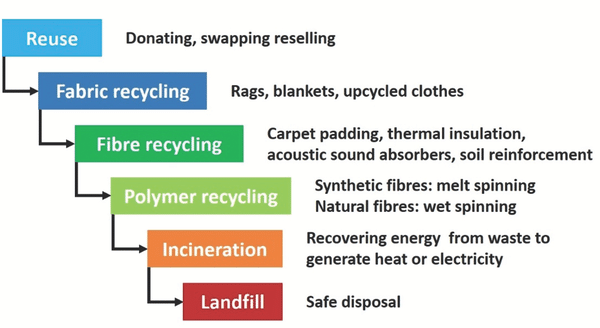

Automated sorting technology could allow the industry to transform non-wearable textiles which currently have no other use beyond landfill, downcycling, or incineration into a valuable feedstock to be recycled into textile waste. One of these is Fibersort, a Near Infrared (NIR) based technology that can classify textiles into 45 distinct fractions by their fiber composition and color. Over the several years, it has been improved and tested to make it ready for commercialization. The Fibersort can now sort up to 900 kilograms of textiles from postconsumer waste per hour.

Fibersort is Now Ready for The Market.

The tech’s effectiveness is mainly dependent on the market that will enable the transformation of materials from textiles to new sources. Its Fibersort consortium of project participants Circle Economy, Valvan Baling Systems, ReShare, Procotex, Worn Again Technologies, and Smart Fibersorting have collaborated with industry partners to know these markets’ needs, analyze the potential of separated materials, and establish the economics of automated sorting as an essential factor in the process of recycling textile waste. The results of these efforts are published in the project’s publications, and Fibersorted materials are commercially available to other organizations to assess their use in recycling textiles into textiles.

Innovation Will Help Fight The Odds

There are numerous opportunities to incorporate automated sorting technology and recycled textiles from post-consumer waste throughout this value chain. In recent years, technological innovation has accelerated in this market area. However, many challenges remain to ensure the sustainable implementation of these technologies, their technical and financial viability, and the potential to increase the scale. Sorters, collectors, recyclers, manufacturers, brand owners, and policymakers are all able to take advantage of the potential and responsibility to tackle these issues. Even though it is true that the Interreg NWE Fibersort project reached its end deadline in March 2020, members of the Fibersort consortium are planning to continue striving towards this goal and also encourage others to join in the effort.

Also Read: What Is the Perfect Impactful Equipment Used for Construction?

Fibersort: the end to a venture, a beginning of a new adventure

This 12 of the 12th of March, the Fibersort consortium will officially launch the new Fibersort technology. It is hosting an online webinar that will explore essential project outcomes talk about the experiences of the sorters, collectors, recyclers brands, and other stakeholders who have made this happen. Please find out how we can close the loop of textiles and welcome input and suggestions from the sector to bring about long-lasting changes in the industry.